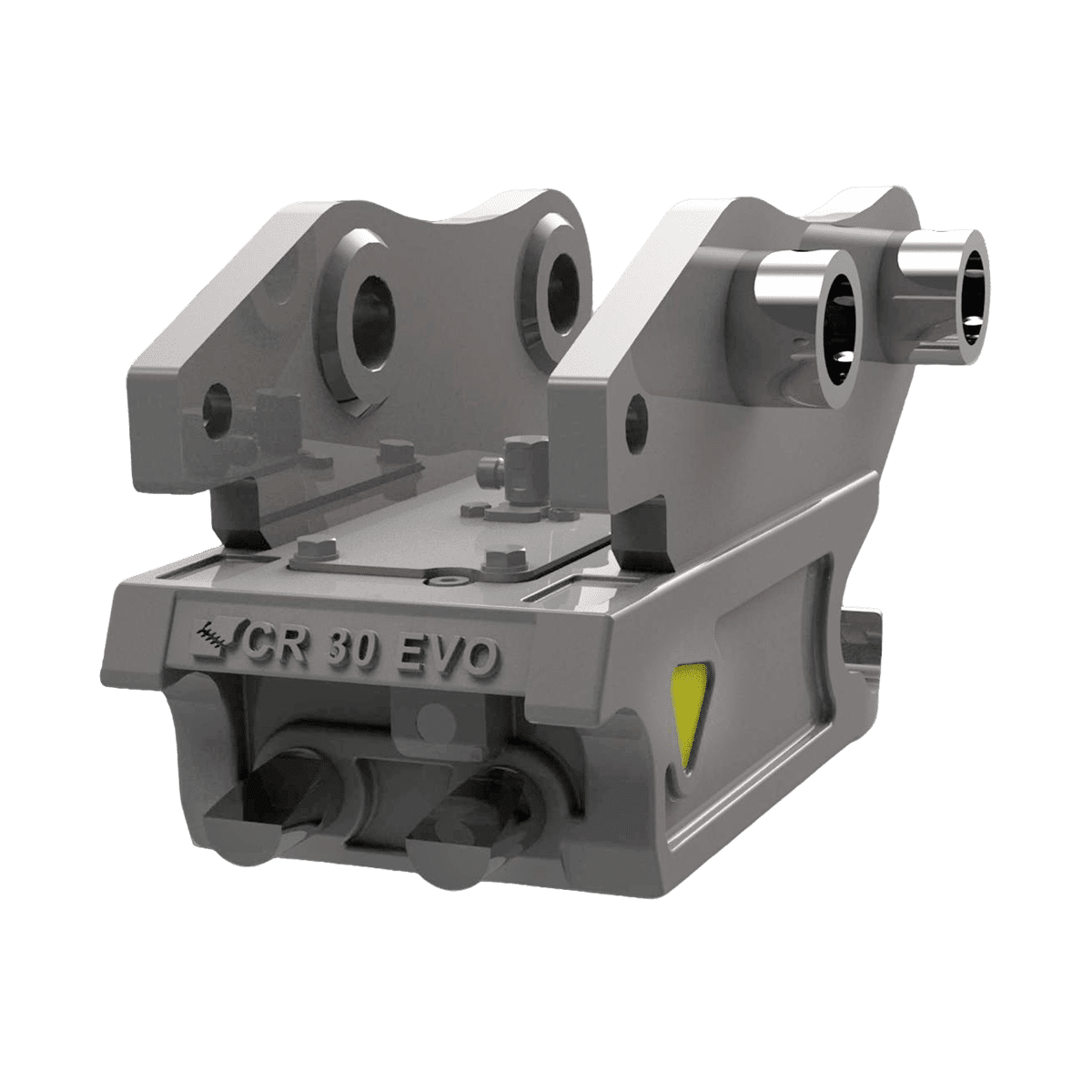

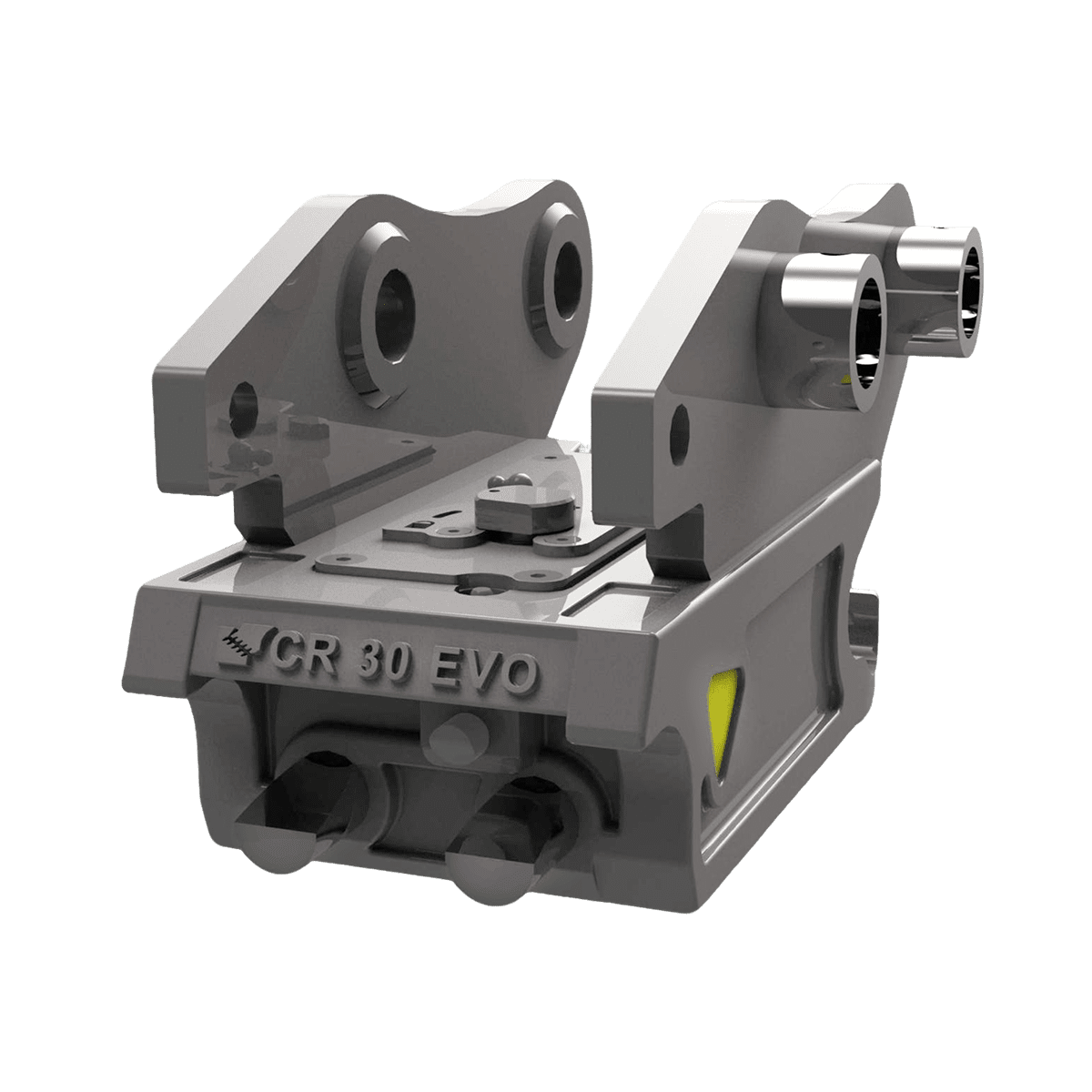

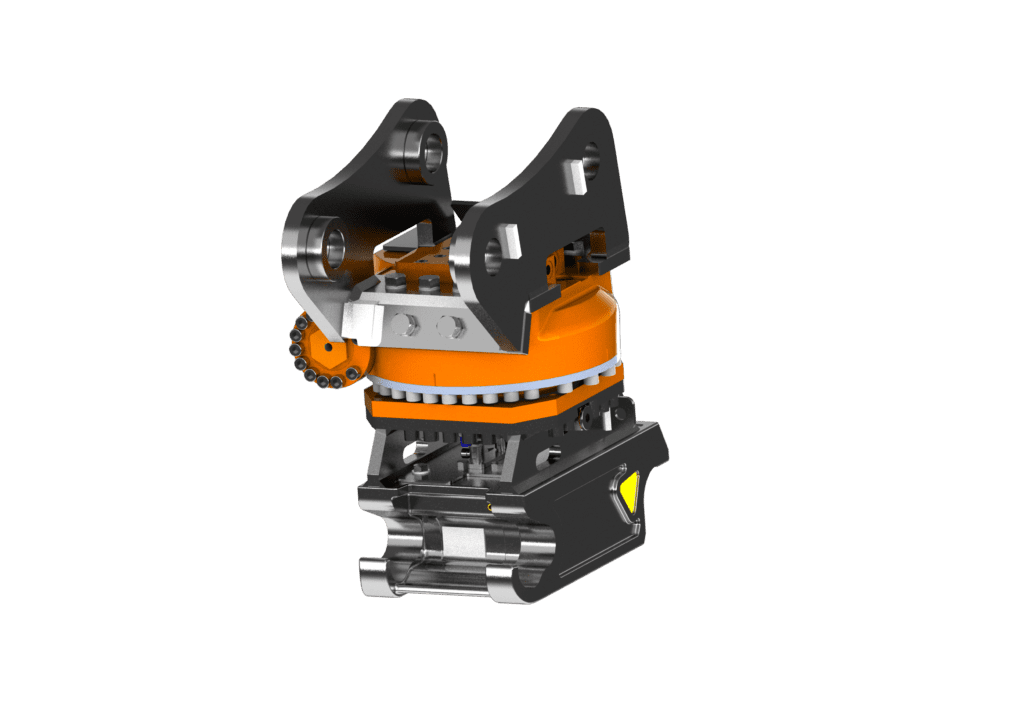

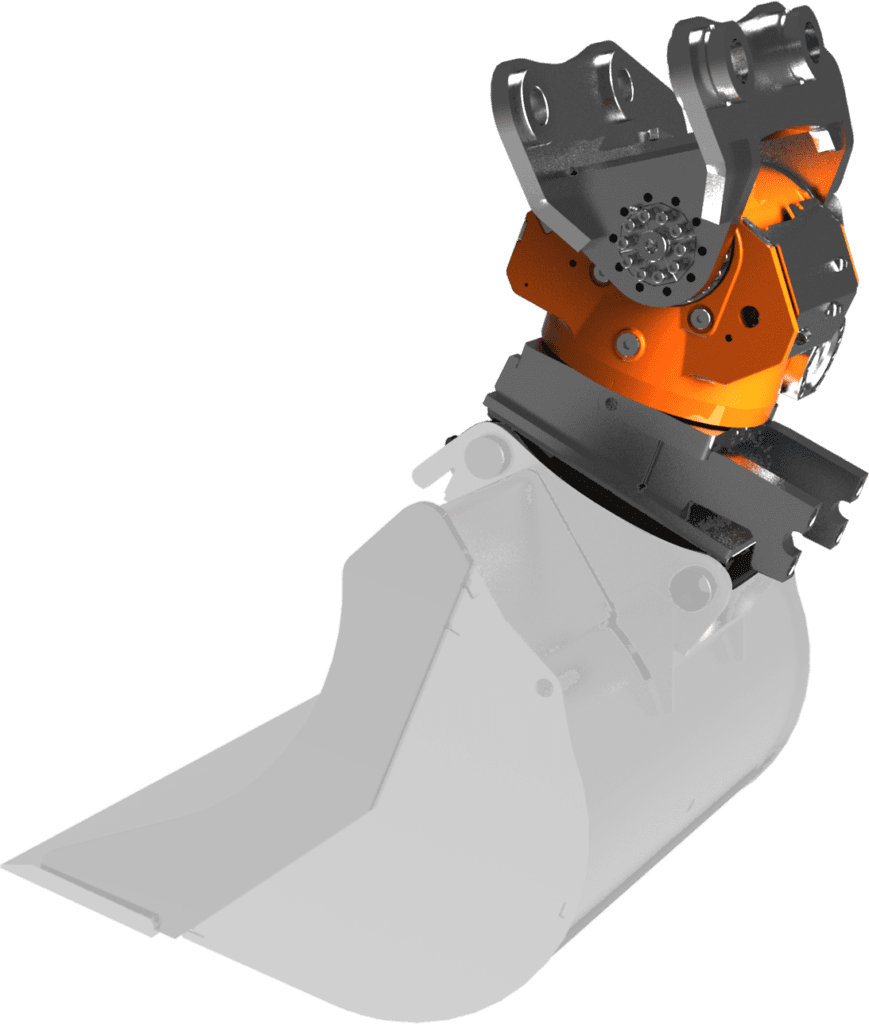

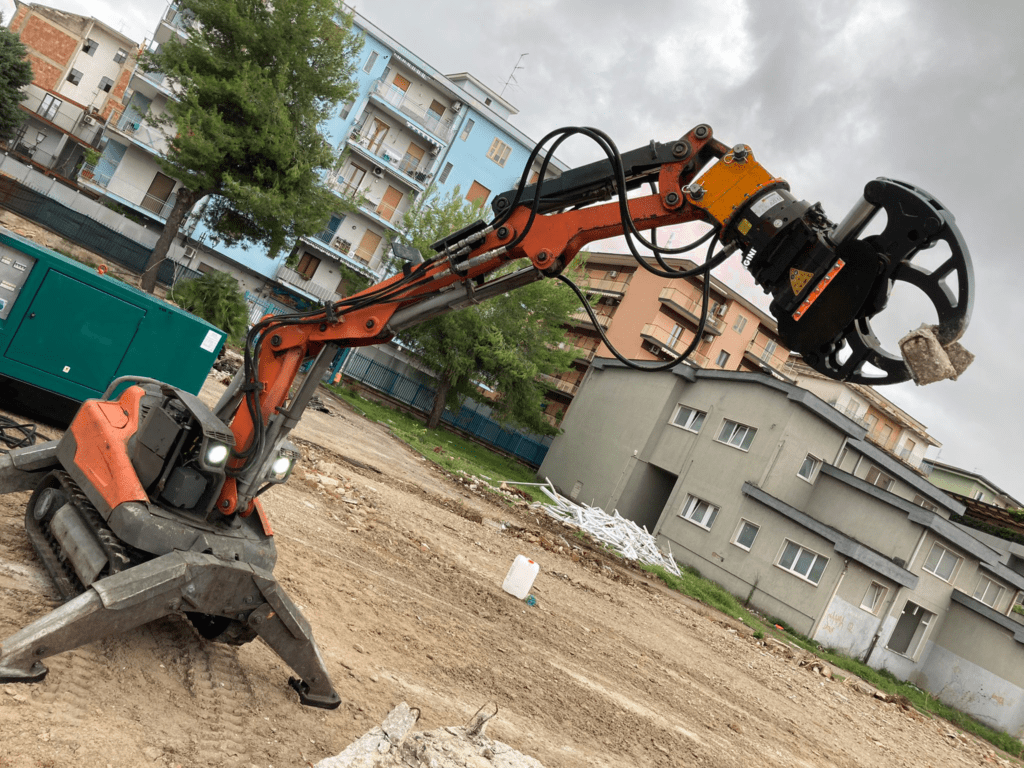

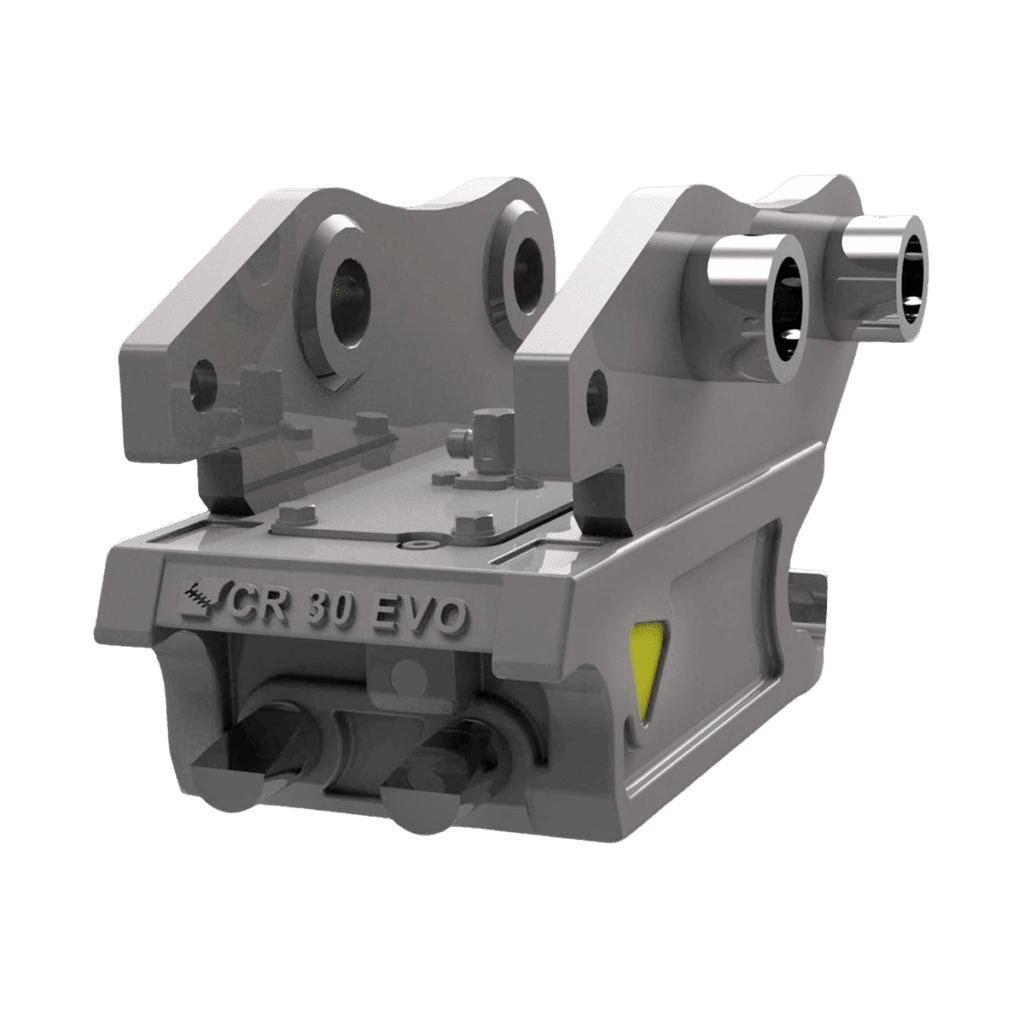

CR TWIN LOCK - D.E. EVO

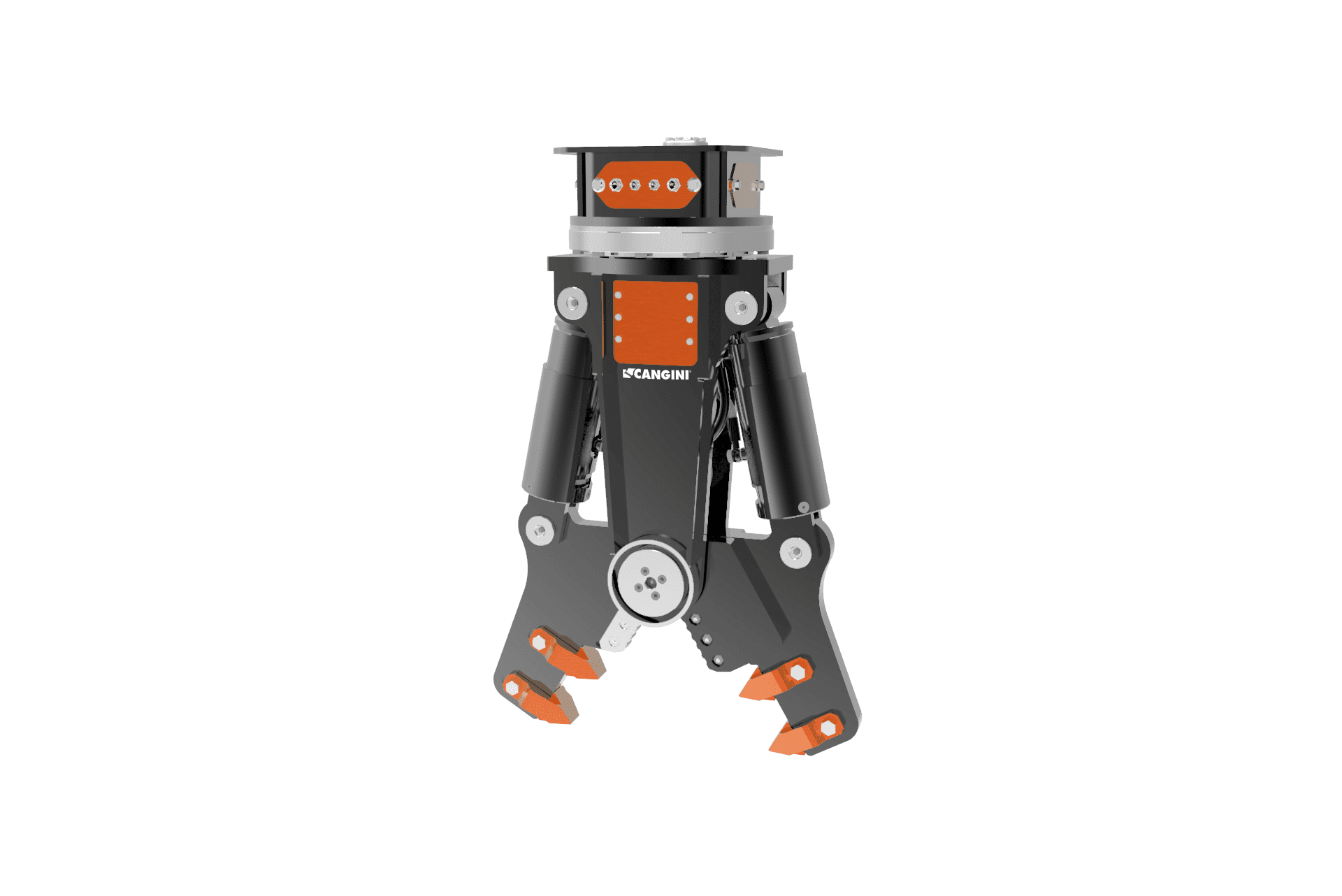

- Backhoe Loaders, Excavators, Quick Couplers

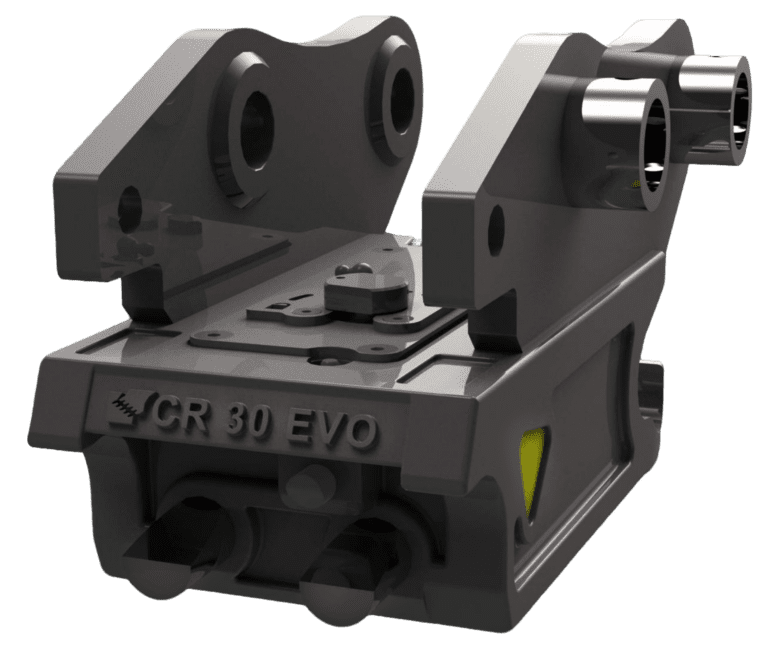

The CR Twin Lock D.E. Evo represents an innovation in the field of quick-release couplings for excavators, introducing a technologically advanced design that integrates several innovative features.

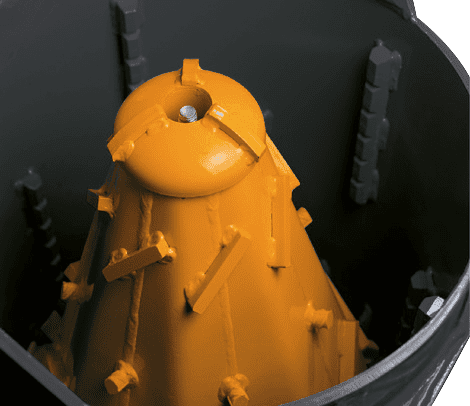

Designed with a high-strength cast body, the CR Twin Lock D.E. EVO incorporates channelled lubrication, the patented Visual Check system and anti-fall devices on the front forks, which comply with the UNI EN 474-1:2022 standard.

This fully hydraulic quick coupling requires a double-acting line feed. The CR Twin Lock D.E. EVO sets a new benchmark for safety, efficiency and reliability, ensuring superior performance in all operating conditions.

Find out how this state-of-the-art solution combines technological innovation and security.

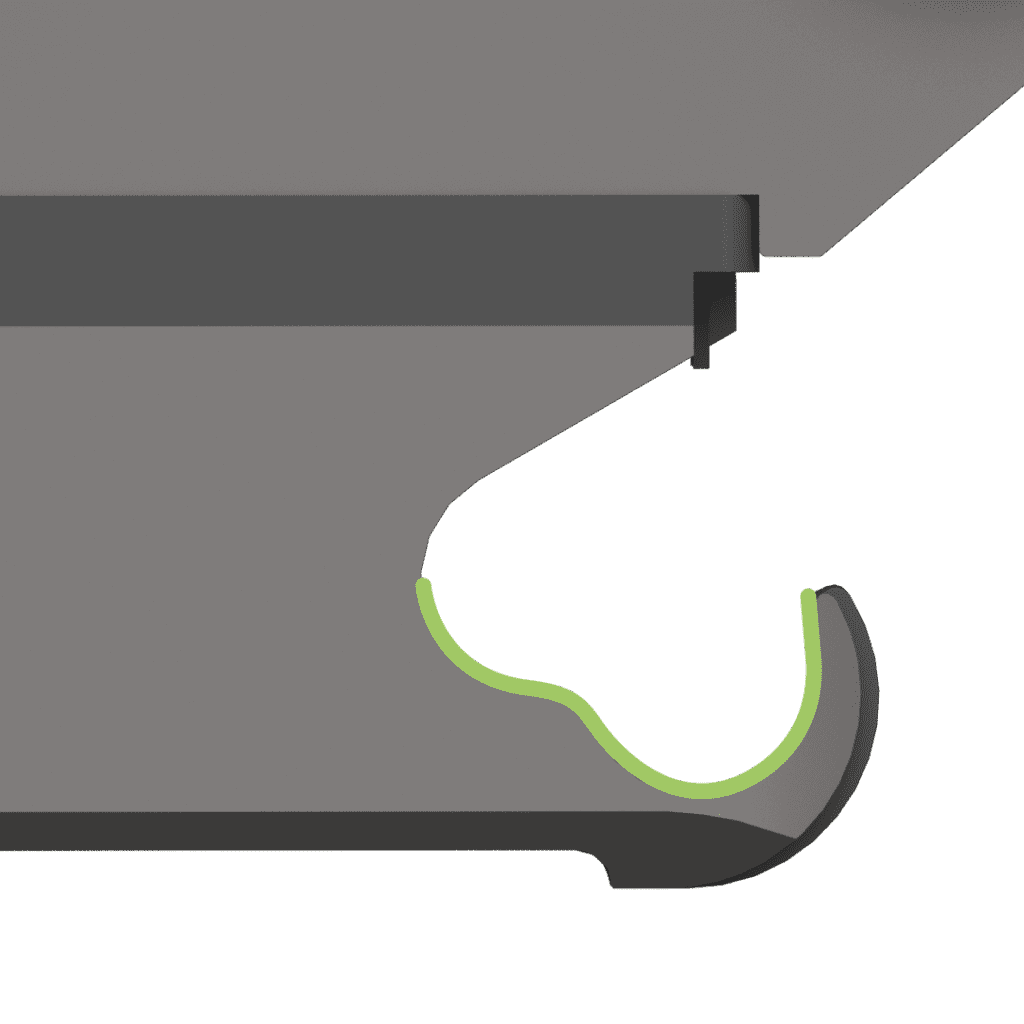

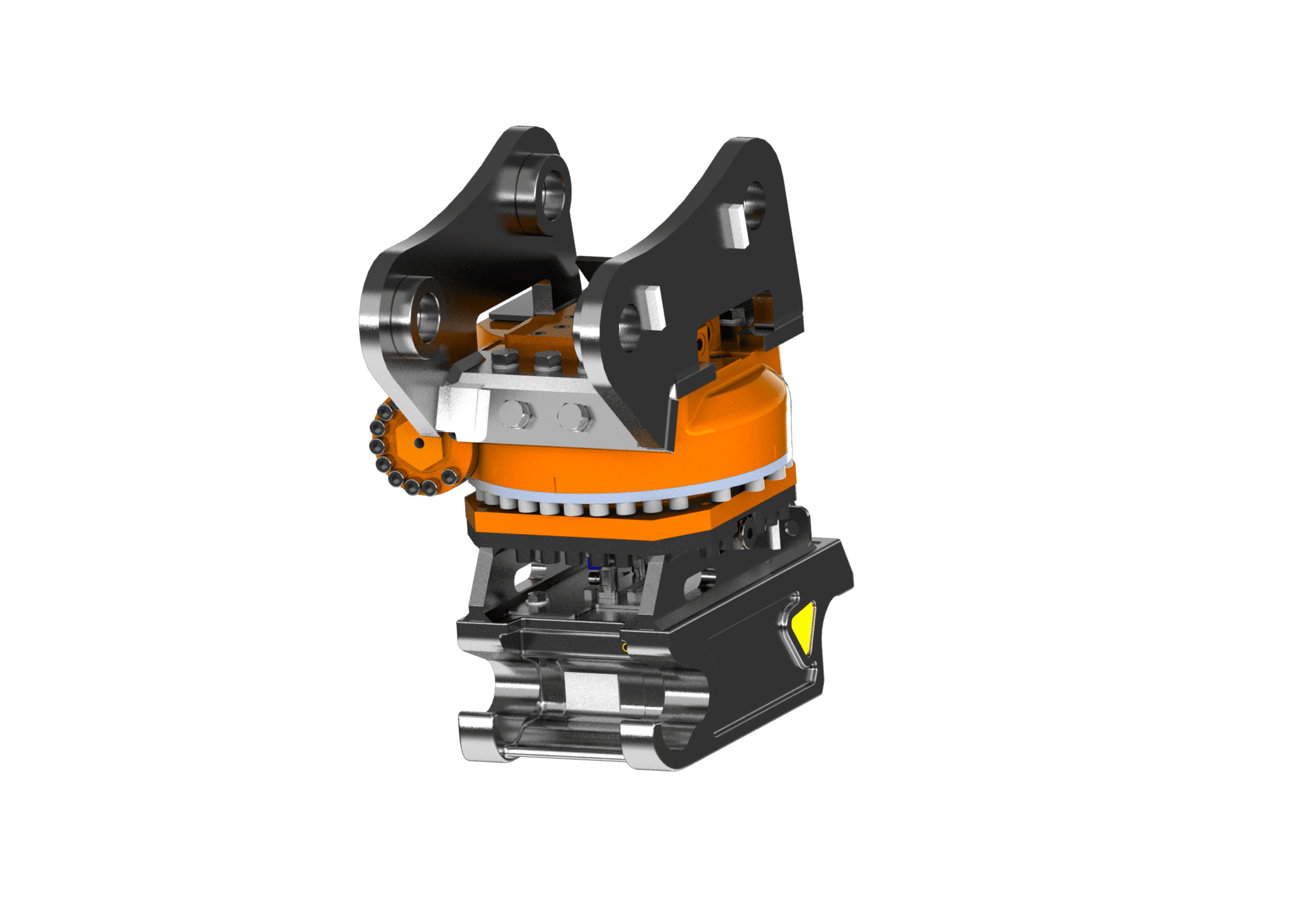

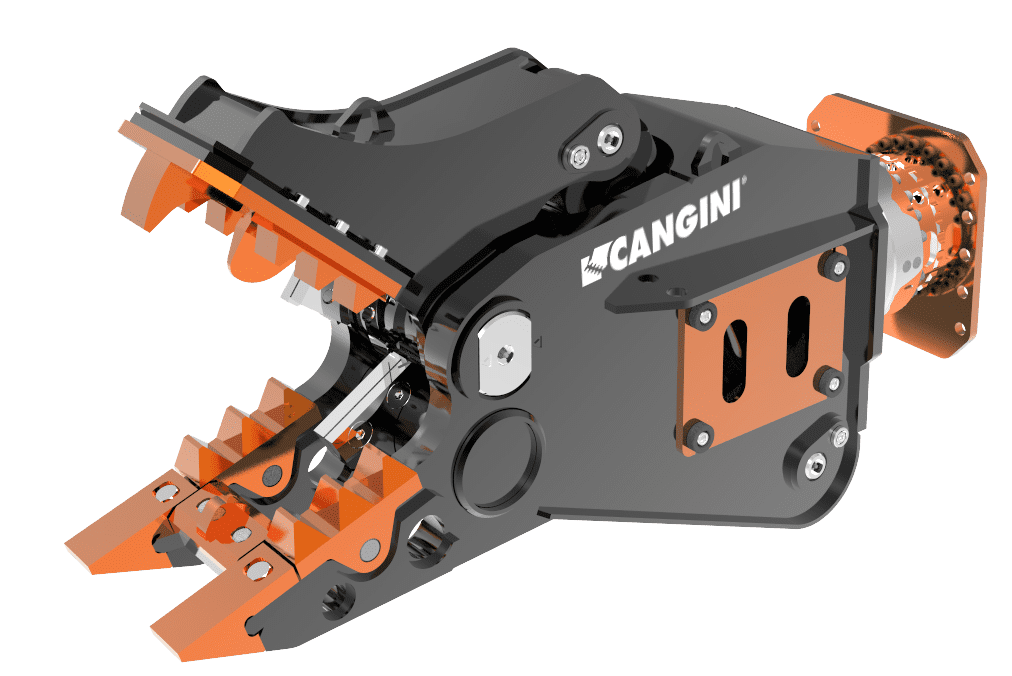

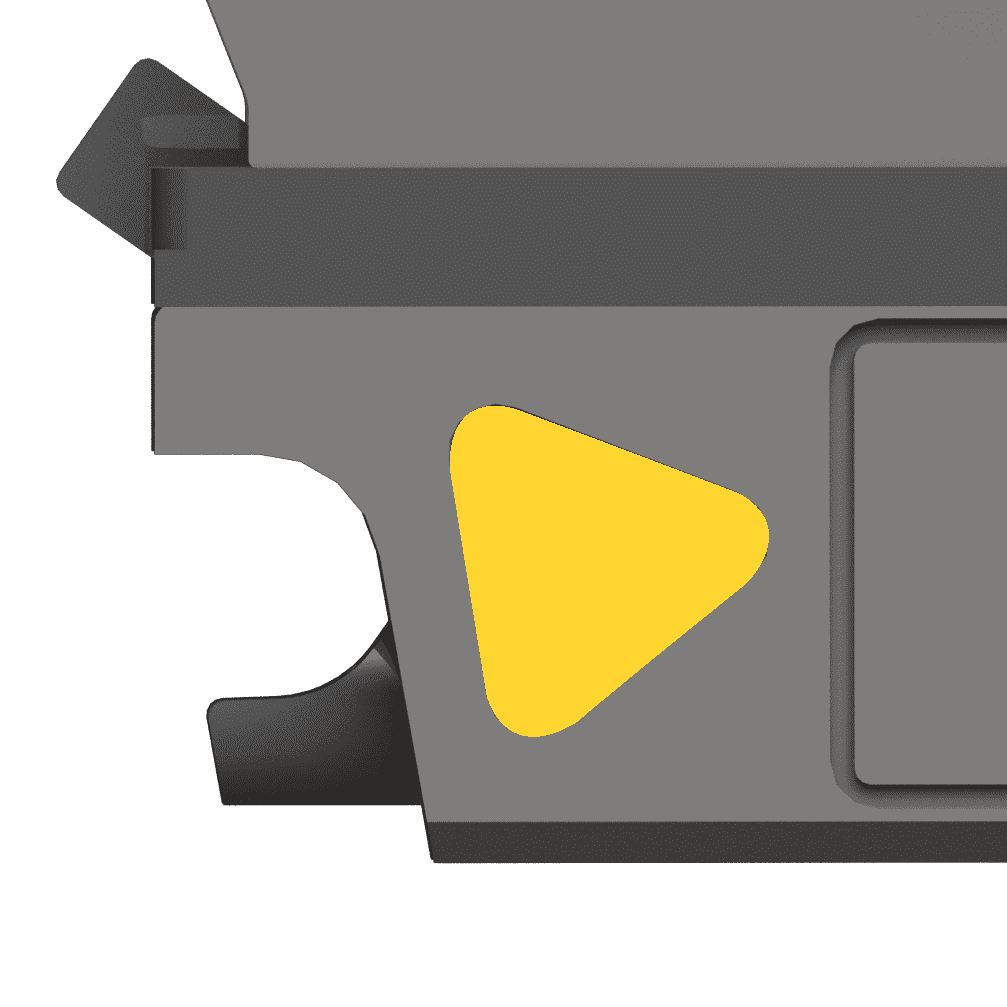

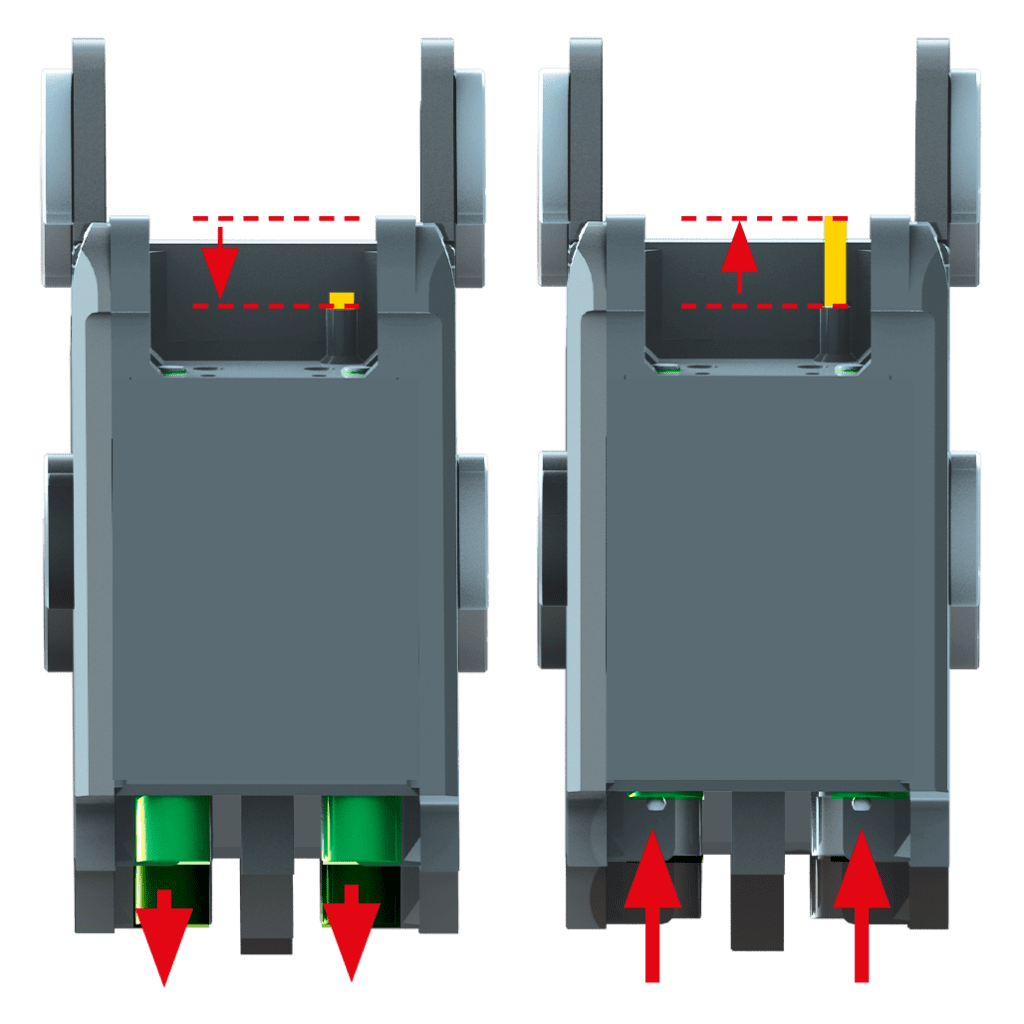

VISUAL CHECK INDICATORS

SIDE VIEWER

The new triangular ‘Safe Check’ side indicator allows the coupling status to be checked for increased safety.

FRONTAL VIEWER

Thanks to the visual front indicator, the coupling status can be checked directly from the cab.

FALL PREVENTION FORK