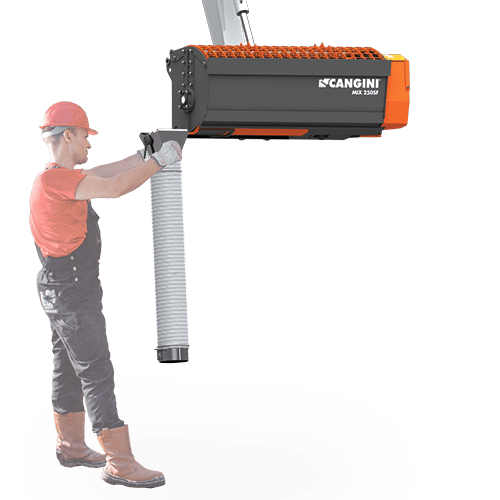

MIXING BUCKET SAFE DISCHARGE FOR EXCAVATORS MIX-FS

- Attachments for Excavators, Excavators

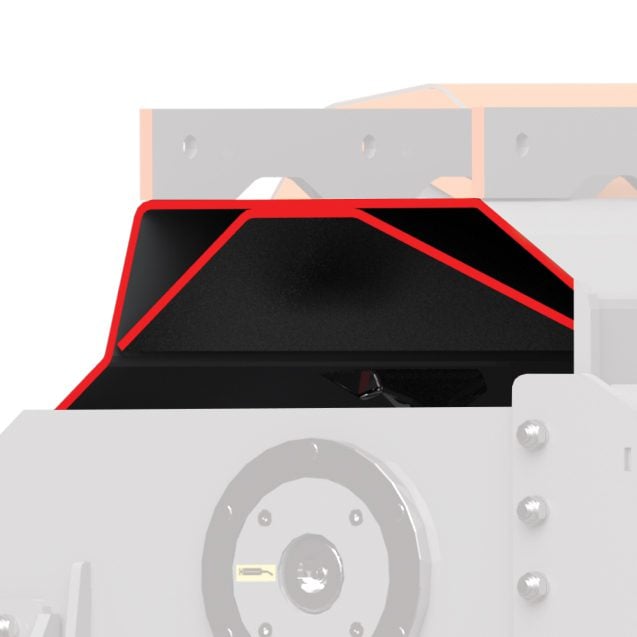

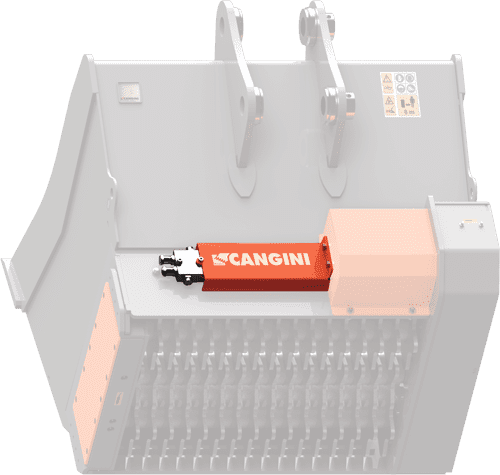

Safety first thanks to our patented system: simply connect the side discharge pipe, in a completely safe position, and guide its travel towards the central discharge position from the cab, without having to stand underneath the bucket.

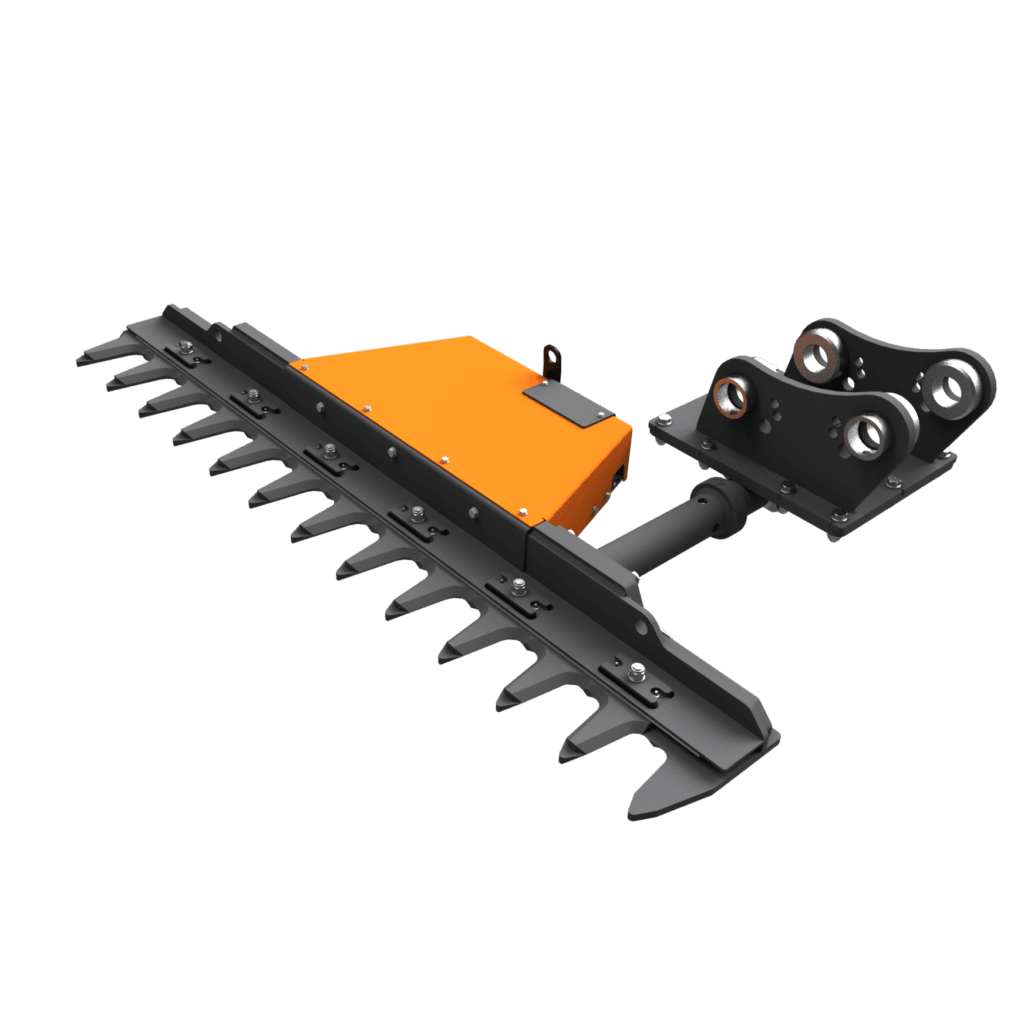

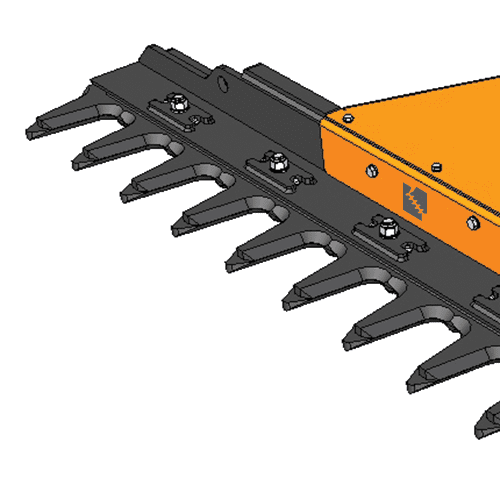

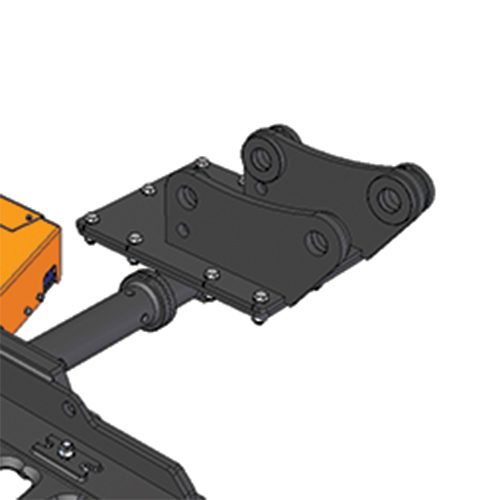

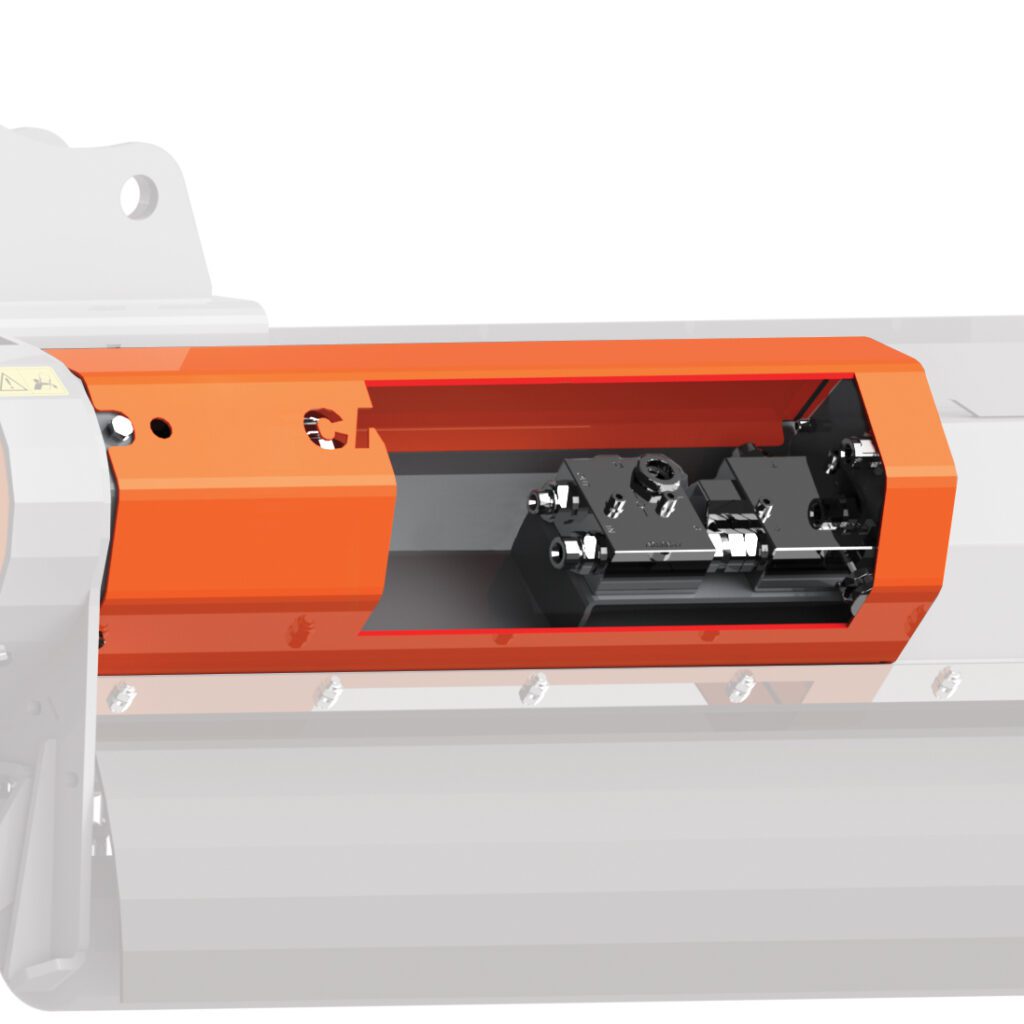

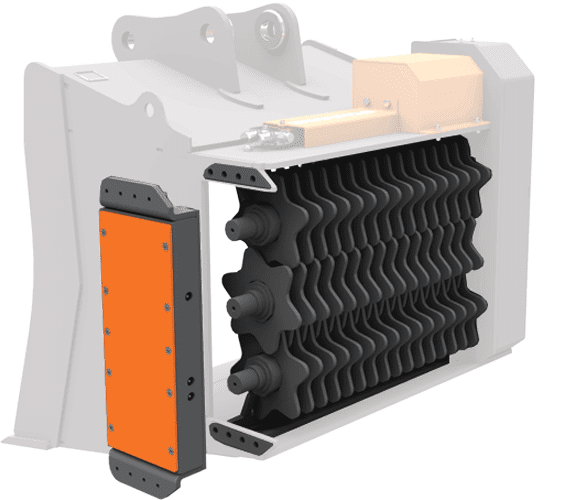

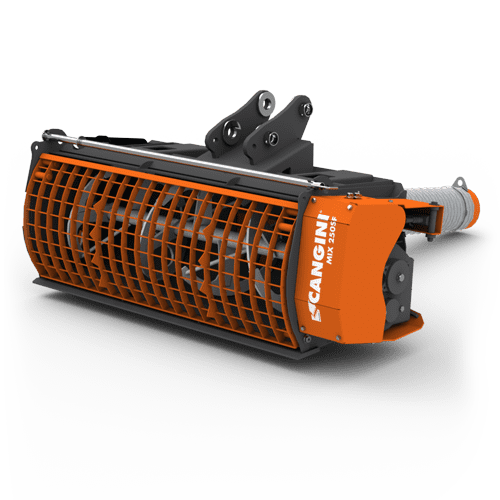

Applicable on excavators, the Cangini mixer bucket is designed to speed up on-site concrete production. Aggregates are loaded using the bucket mounted on the machine. Thanks to the auger, as water and cement are added the mixture is created and pushed towards the middle of the bucket, ready for discharge. The discharge pipe is connected at the side, in a totally safe position, and the operator’s presence underneath the attachment is not required. In fact, the shift to central position is controlled by the hydraulic system and operated from the cab. What’s more, if necessary a guide rod fitted to the bottom end of the pipe allows the operator on the ground to direct the discharge pipe outlet to the working position, again without approaching the material discharge zone. The gear motor guarantees high system performance, while the mixer’s rugged structure, combined with the tough auger in hard-wearing HB400 steel, ensures a long operating lifetime.

SAFETY

The operator locks the discharge pipe to the side, in safe position. In fact, the shift to central position is controlled by the hydraulic system and operated from the cab.