Front Screening Bucket V-F

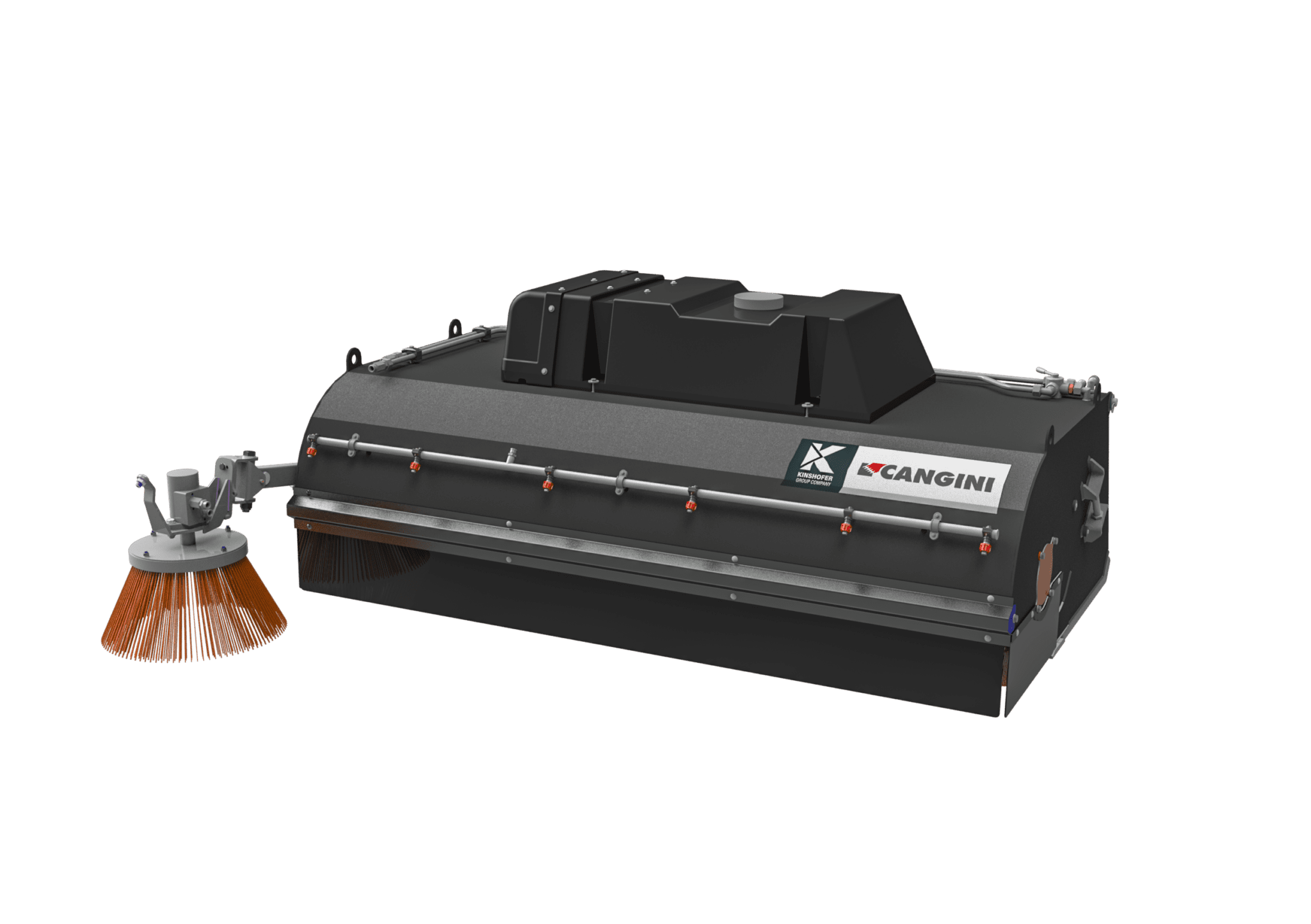

- Backhoe Loaders, Frontal Attachments, Skid Steer Loaders, Telehandlers, Wheel Loaders

Screening jobs on site have never been so quick and efficient!

The V series has been equipped with a patented system that allows you to replace sieving shafts rapidly, without intervening on transmission. Time saving ad cost reduction are the significant advantages you are granted with.

Ideal for selecting and screening organic material, the Cangini front screening bucket enables material to be recovered and managed directly on site, increasing the job’s productivity and economic returns.

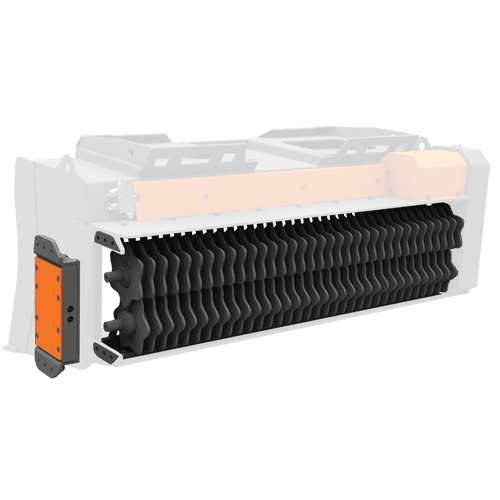

The screening operation is carried out by a hydraulic screening unit equipped with rotating HB400 knives.

The size of the screened material can range from 0 to 20 mm and from 0 to 35 mm with a standard setup. Customized shafts can be also supplied.

5 models are available applied on skid and mini skid, wheel, telescopic and backhoe loaders.

Mainly used in the screening and recycling industries, it is also suitable for the horticultural sector, for mixing soil and peat, for cleaning and reclamation of fields, or to cover drainage channels with materials resulting from digging works.

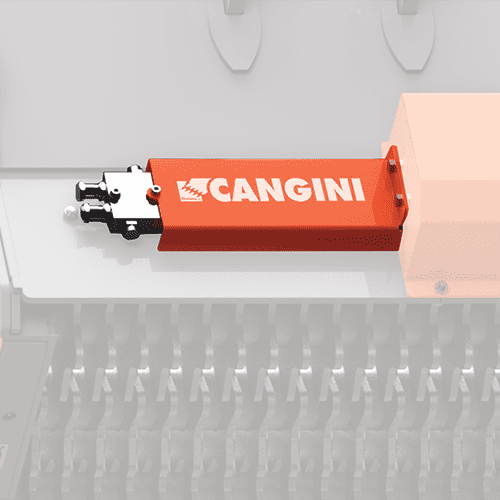

REDUCED MAINTENANCE TIME AND COSTS

Thanks to the patented system, it is possible to replace shafts quickly and change the screened material size, without intervening on the transmission unit.

RESISTANCE

All knives are made in HB400 steel, much more resistant than standard construction steel. Therefore, the equipment is robust and durable.

LONG WORK LIFE

The shock-proof valve protects the motor against pressure peaks occurring during work, guaranteeing a long work life to the equipment.