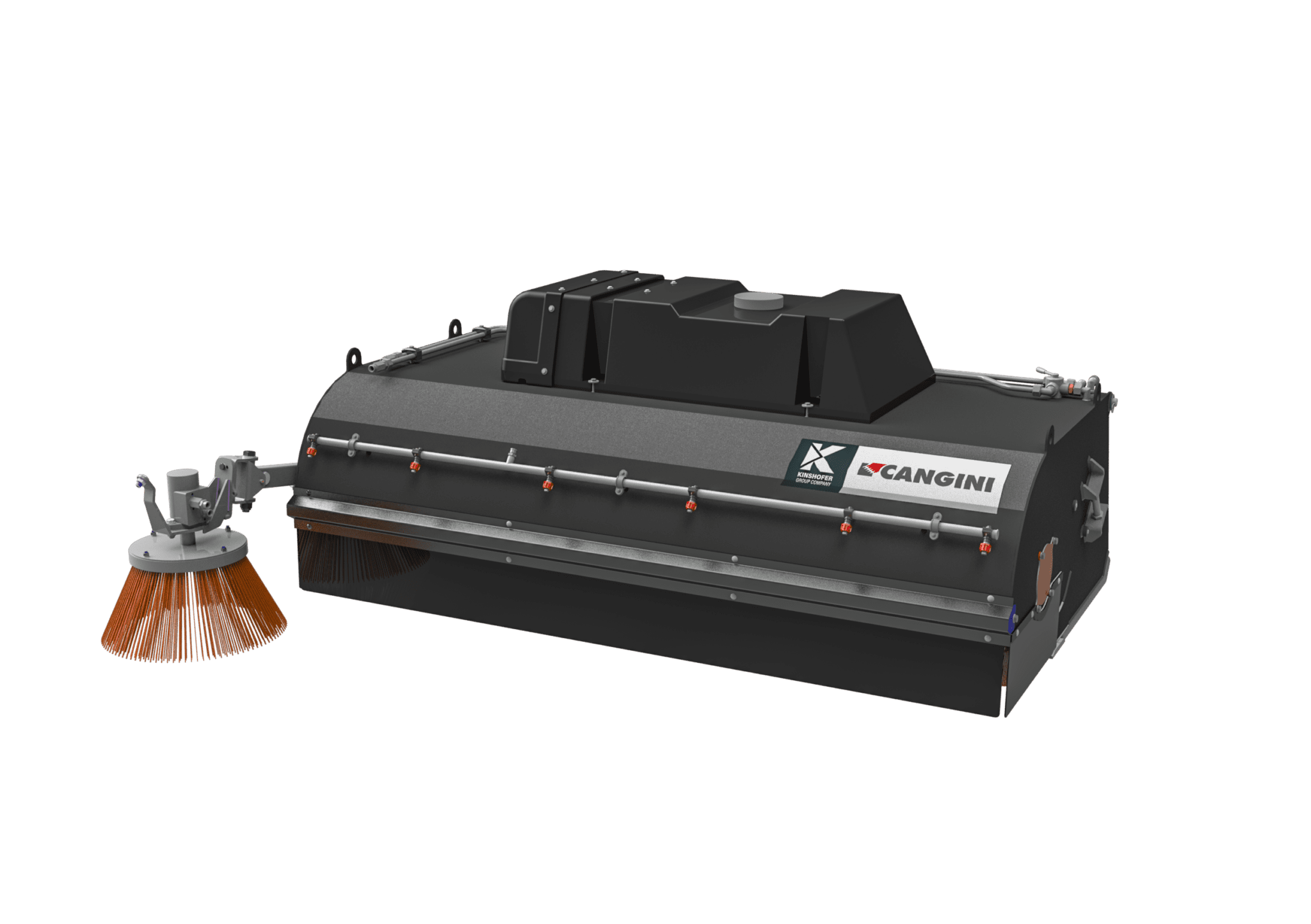

MULTISCREENING TWIN-F BUCKET FRONTAL COUPLING

- Backhoe Loaders, Frontal Attachments, Wheel Loaders, Telehandlers

One step ahead. Conceived to satisfy your operational and safety needs. Doubled performance, great visibility from the cab.

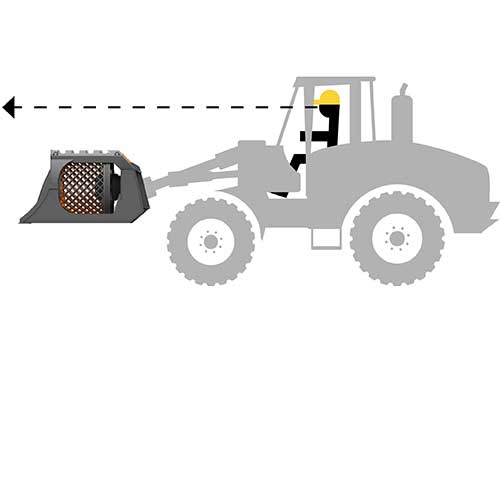

The VMS TWIN F20 model for frontal coupling features an extremely innovative, compact design. The horizontal coupling of the two screening drums doubles the operational capacity, while maintaining the tool’s height unvaried and consequently the visibility from the cab unimpaired. Just as for the whole Multiscreening range, the screening size variation system allows for real-time selection of the screening size from 25 to 60 mm, straight from the cab and without having to replace any mechanical part.

The horizontal coupling of the two screening drums doubles the operational capacity, while maintaining the tool’s height unvaried and consequently the visibility from the cab unimpaired. Just as for the whole Multiscreening range, the screening size variation system allows for real-time selection of the screening size from 25 to 60 mm, straight from the cab and without having to replace any mechanical part.

The two rotary drums on each other: controlled by a hydraulic cylinder, the inner drum’s movement allows to change the size of the holes for material screening. This feature guarantees excellent versatility to the bucket.

No need to replace any mechanical part of the screening bucket, no machine-down time, no need for personnel on the ground close to the equipment.

Ideal for screening rubble from demolition, from trench infills and from the clearing of stony ground, the Cangini front screening bucket enables material to be recovered and managed directly on site, increasing the job’s productivity and economic returns.

DOUBLE PERFORMANCE, MAXIMUM SPEED

Double operational capacity thanks to the two rotary drums, paired in a single frame. Maximum operational speed thanks to the use of a single tool to obtain different sizes of the sieved material without having to replace any mechanical part. High working speed thanks to the use of a single attachment for screening different sizes, without the need to replace any mechanical part.

OPTIMISED VISIBILITY FROM THE CAB

The horizontal pairing of the drums does not modify the tool’s height and consequently the visibility from the cab is unimpaired.

VERSATILITY

Each screening unit (HB400 wear-resistant steel) consists of two rotary drums sliding on one another: controlled by a hydraulic cylinder, the inner drum’s movement allows to change the size of the holes for material screening. This feature guarantees excellent versatility to the bucket.