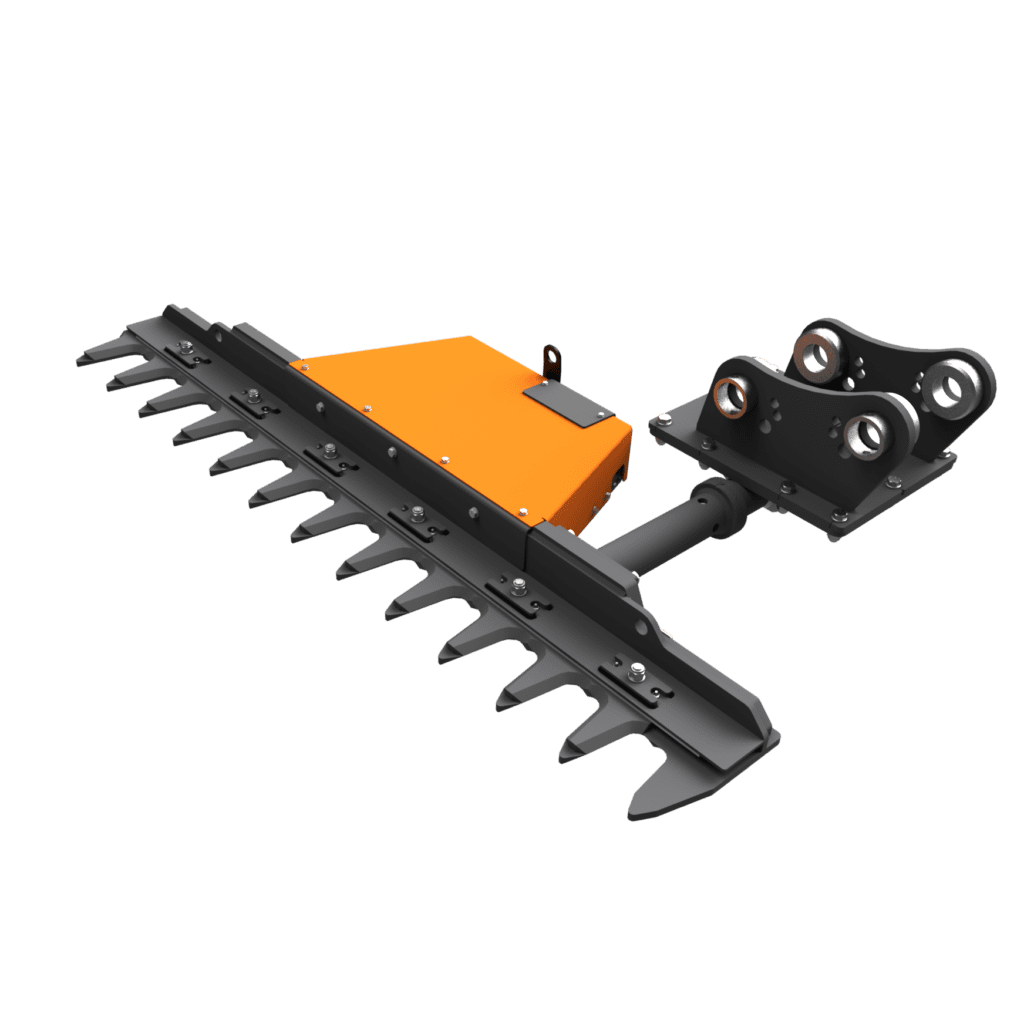

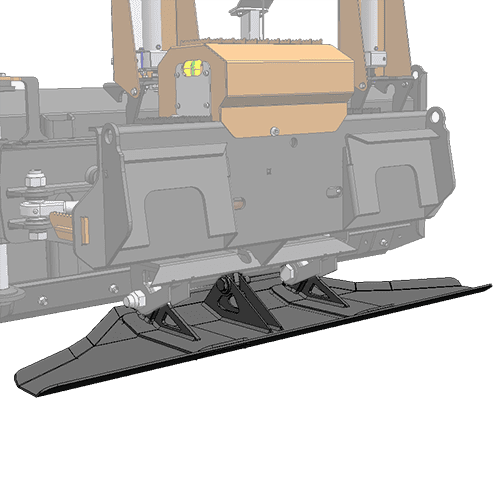

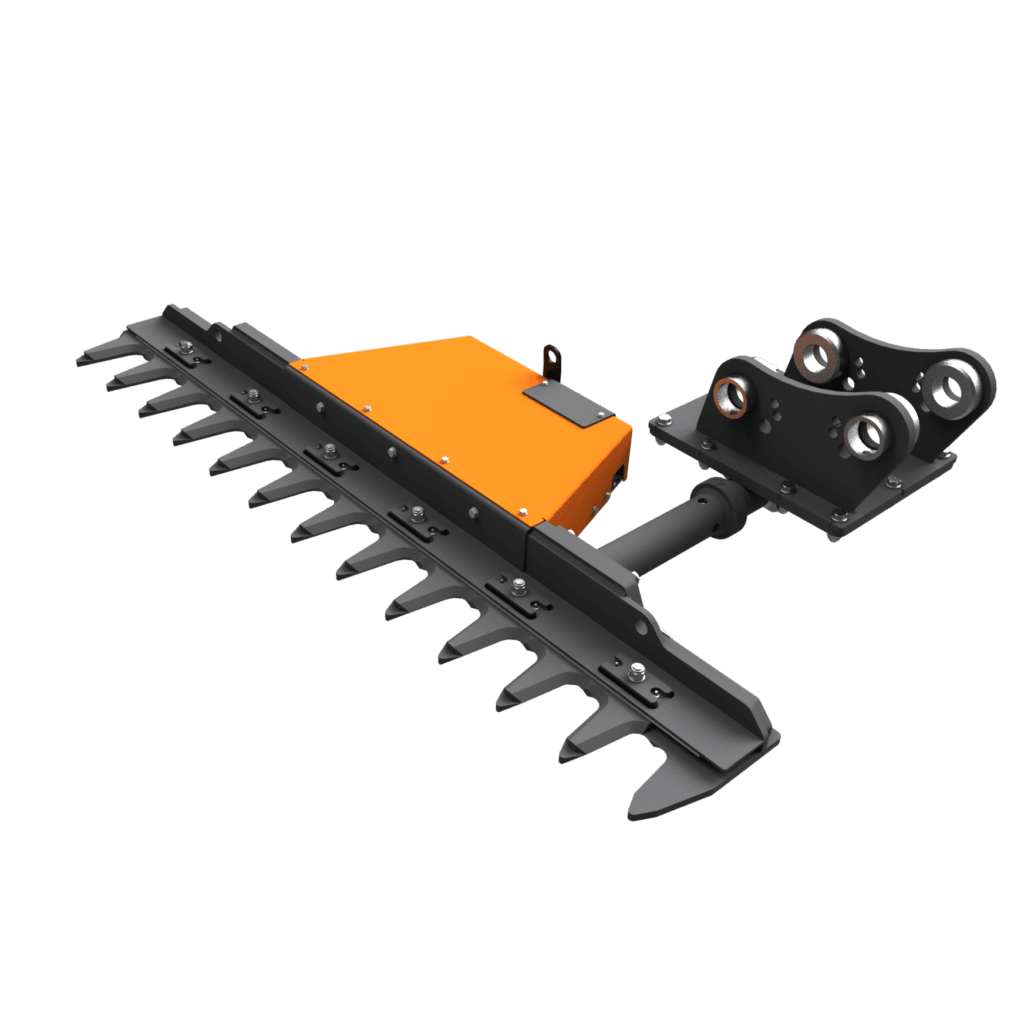

Sharp-Cut Branch Cutter Bar BTC

- Attachments for Excavators, Backhoe Loaders, Excavators

The best attachment to guarantee effective pruning. It is resistant and long-lasting, capable of withstanding the heaviest stresses thanks to its HB450 steel blades.

The new generation “Sharp-cut” branch cutter bar represents the ideal choice for forest conservation and enhancement, thanks to its clean and precise cut that safeguards plant regrowth.

It is a robust equipment, suitable for pruning branches and bushes up to 100 mm and it does not ruin the plant because it performs a decisive cut without tearing.

Fast cut: 195 strokes per minute in the 50-150 and 50-180 models and 86 strokes in the 100-160, 100-190, 100-220 models. The Sharp-Cut line takes full advantage of every machine class, making the equipment highly performing on any tonnage from 2.5 to 14.0 tons.

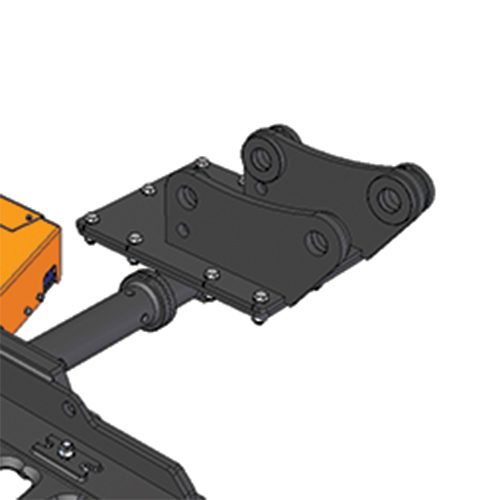

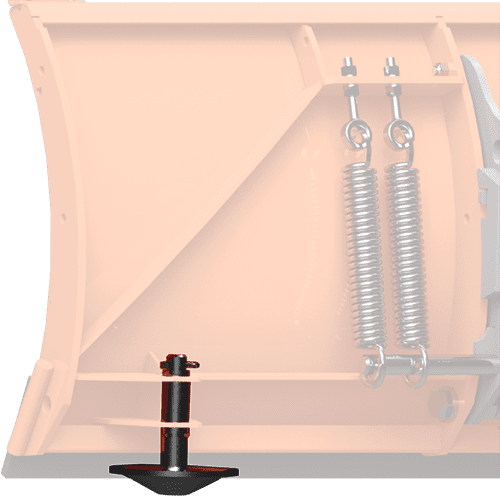

Its compact design guarantees easy handling and possibility of use even in areas with dense vegetation. Highly performing, thanks to its revolving joint it is possible to adjust the bar tilt as needed. It can be applied to either side of the excavator arm, allowing the operator to reach work areas otherwise unreachable through simple arm bending and extension.

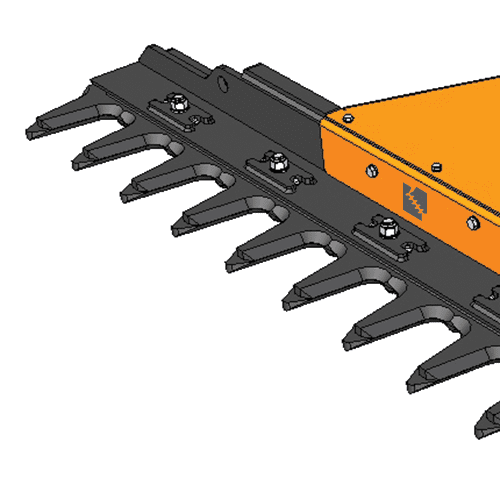

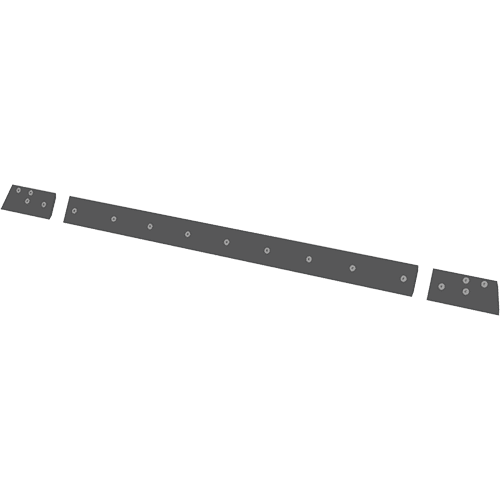

The serrated profile of the blades, in models 50-150 and 50-180, and the double sharpening in models 1000-160, 100-190 and 100-220 allow excellent branch grip, contributing to its “Sharp-cut” result.

RESISTANCE

A rugged attachment able to lop branches up to 100 mm; the blades in HB450 steel, harder than conventional construction steels, withstand the most heavy-duty working conditions.