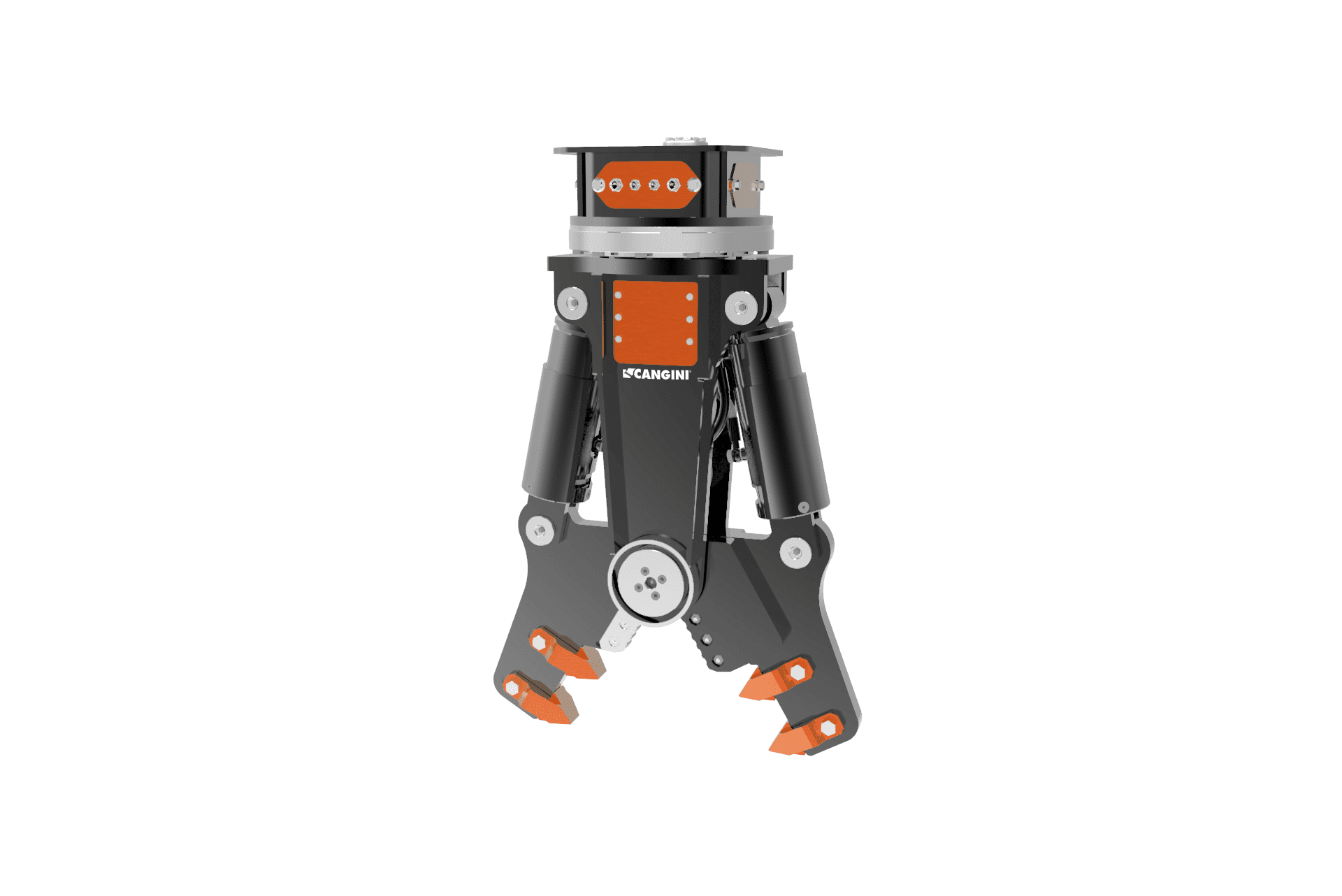

FRONT MULCHER TC-F

- Frontal Attachments, Skid Steer Loaders, Wheel Loaders

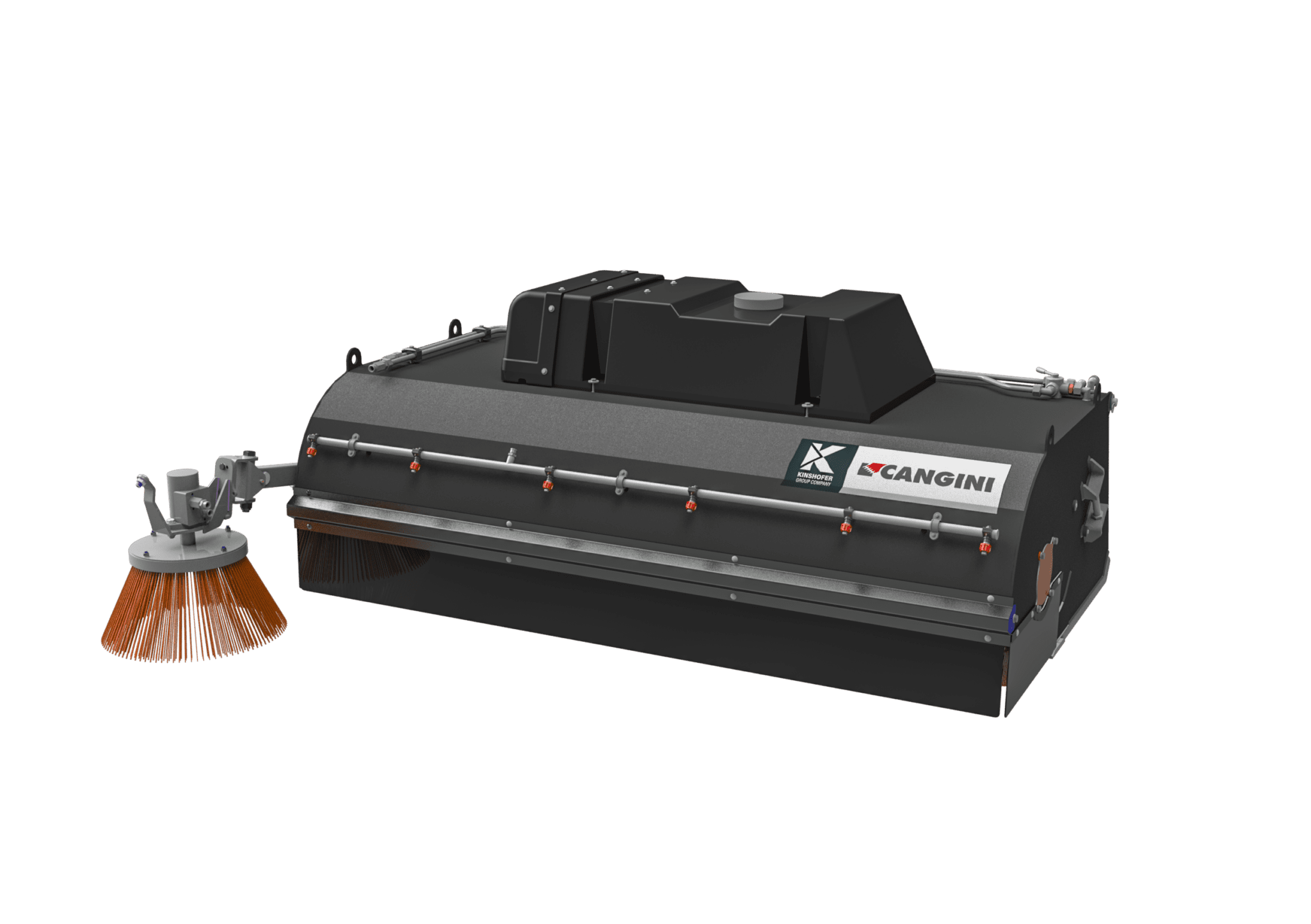

Thanks to its strong frame and great power, our mulcher is the ideal tool for both forest care and park and garden maintenance works.

The heaviest operations such as brushwood clearance and maintenance of public green areas are its ideal working fields.

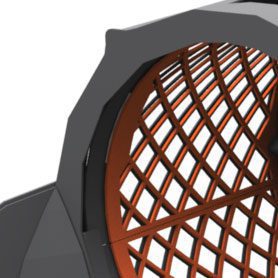

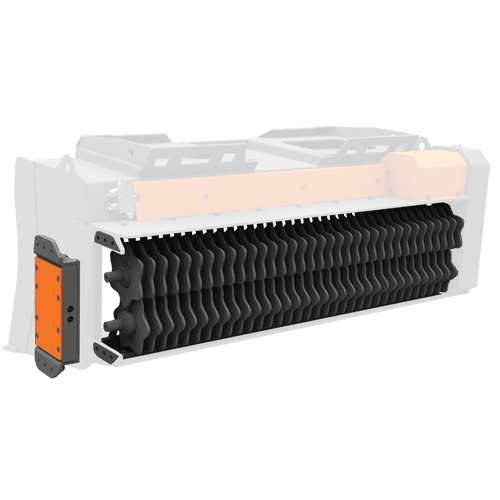

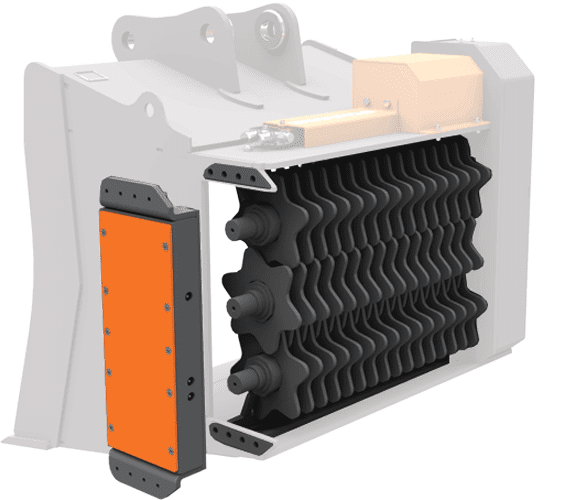

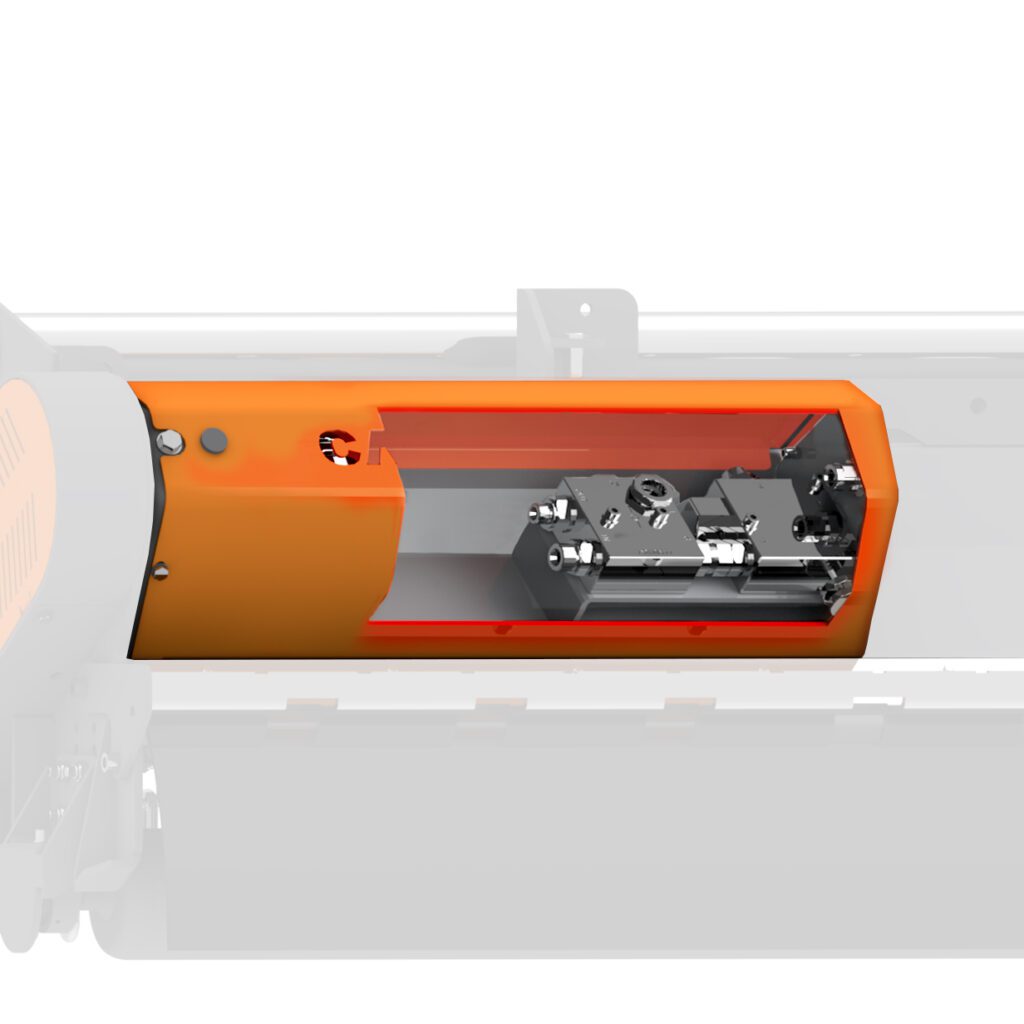

This attachment is rugged and durable, thanks above all to its reinforced casing with double bottom, which provides outstanding resistance to impacts and torsional forces, and also to the shielded bearings of the rollers, which protect them from collisions with material in the mulching area.

The shaft equipped with blades is suitable for mowing weeds and for standard usages. The hammer shaft set-up is especially designed to withstand to heavy works, such as cutting shrubs up to a diameter of 10cm.

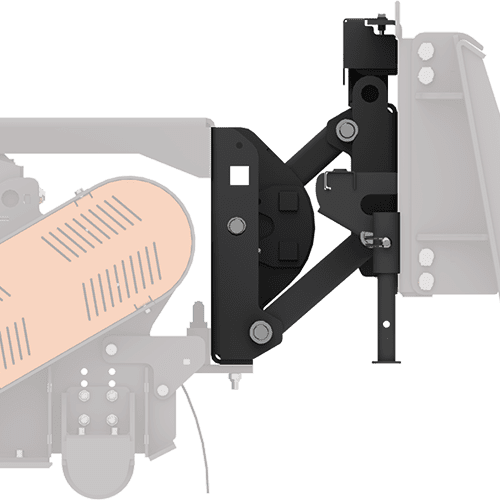

The support roller, adjustable in height, and the machine coupling adjustment slide, make this tool extremely effective and allow the operator to choose the desired cutting mode.

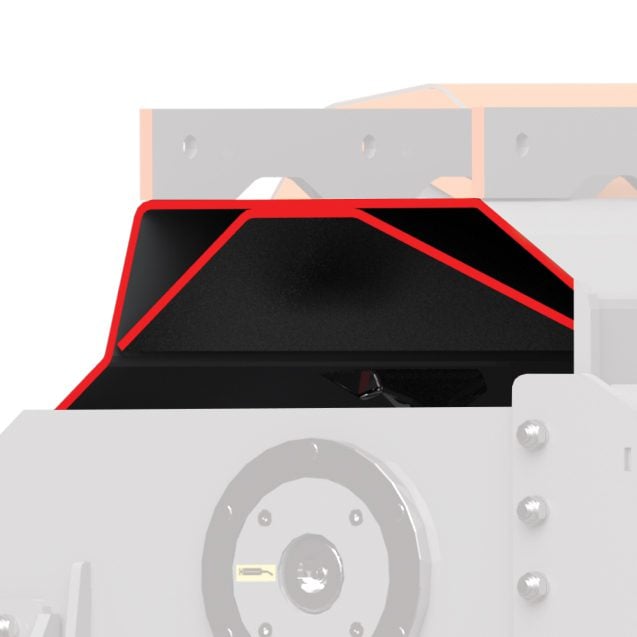

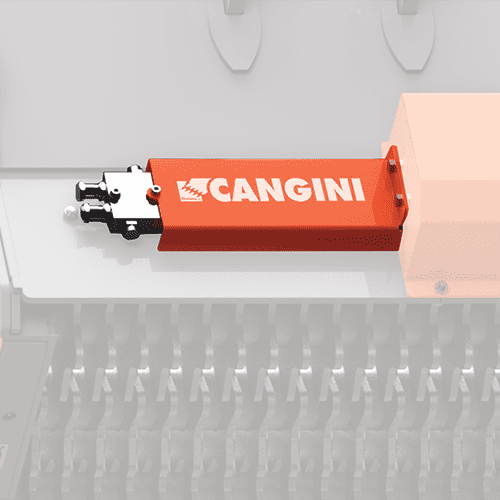

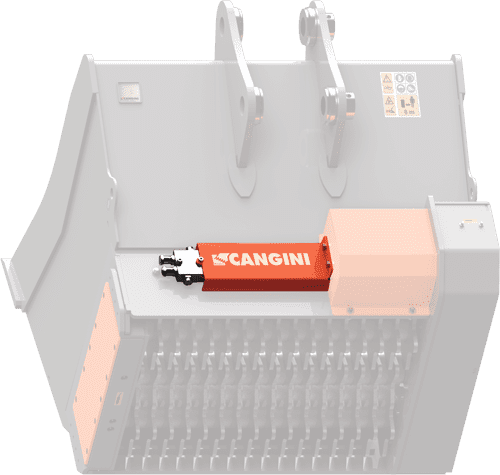

Equipped with floating system and ± 10° self-levelling system to the ground, the Cangini mulcher is an efficient tool suitable for the most accurate works.

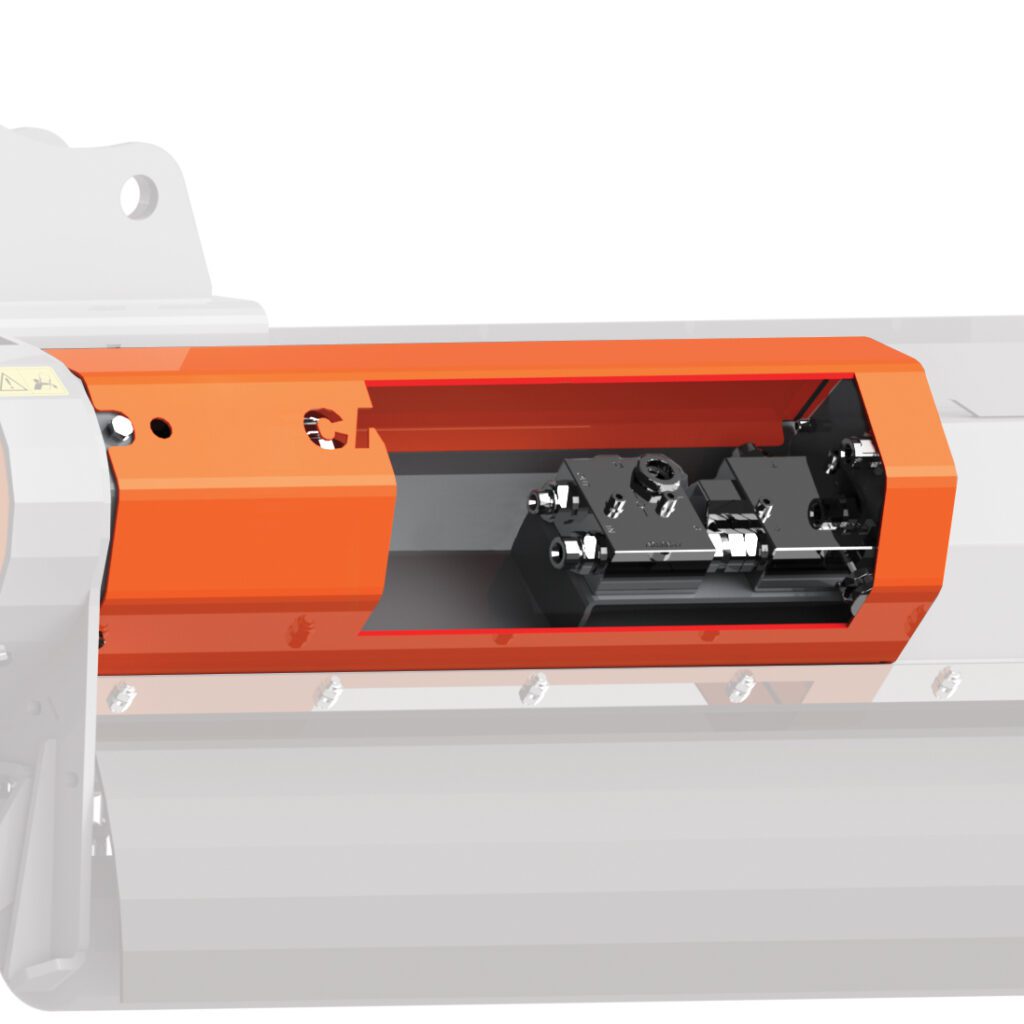

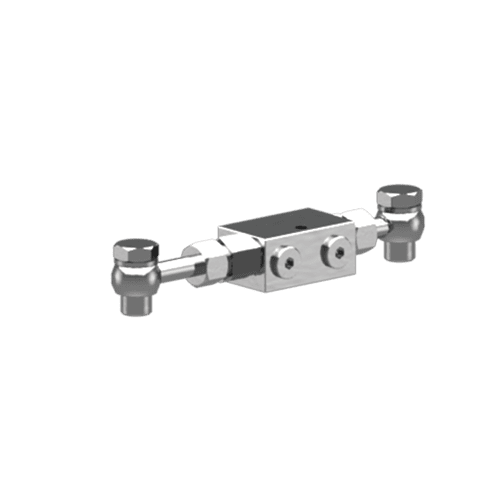

Highly resistant, the mulcher features an integrated valve unit as standard equipment, which optimises engine performance and prevents pressure overloads, thus increasing its work life.

6 different models to choose from: the Cangini mulcher will suit skid loaders, mini skid loaders and skid steers.

STRENGTH

Rugged and durable, thanks to its reinforced casing with double bottom, which provides outstanding resistance to impacts.

ENGINE PROTECTION

An integrated valve unit featured as standard equipment optimises engine performance and prevents pressure overloads, thus increasing its work life.

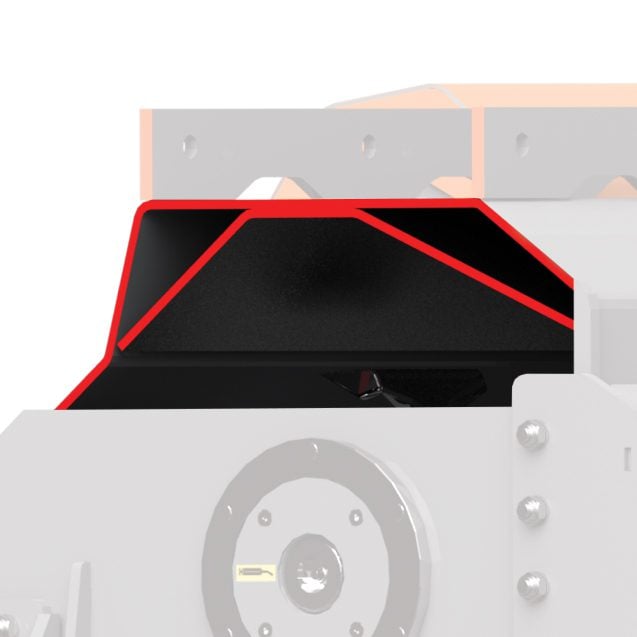

HIGH PERFORMANCES

The floating system allows the mulcher to adapt to the roughest grounds and follow terrain profile, to guarantee thorough mowing.